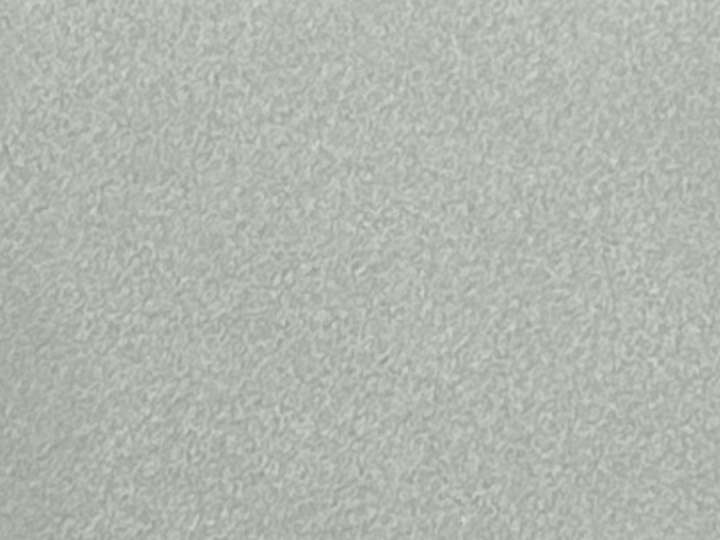

Satin

<Features>

・Small particles applied to the surface create a rugged texture

・Plastic beads are mixed into the paint as an aggregate

<Benefits>

・Scratches and unevenness on the coated surface are less noticeable

・Surface roughness can be controlled by adjusting the thickness of the coating

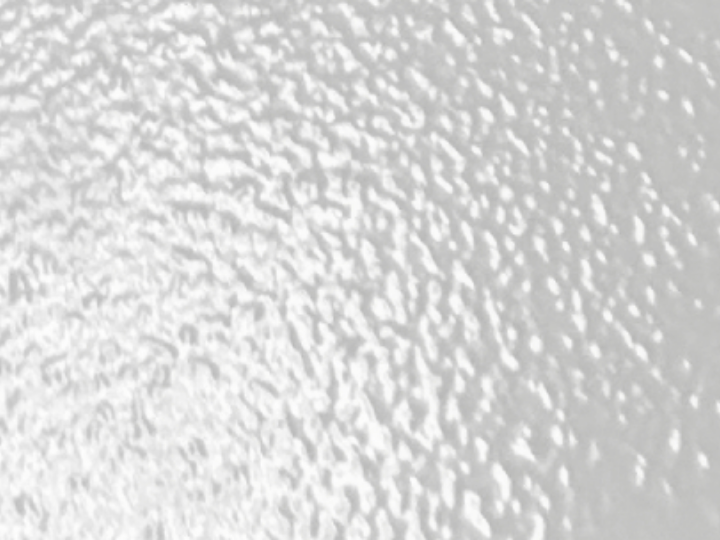

Leather Tone

<Features>

・A textured vinyl leather like pattern with small bumps.

・The pattern emerges from melted resin beads, and changes depending on the temperature and type of resin.

<Benefits>

・A smooth texture that differs from the rough texture of satin.

・Recreates the luxurious and soft feel of leather.

Mild Hammer Tone

<Features>

・The pattern resembles metal being lightly struck with a hammer.

・The pattern can be adjusted by changing the amount of additives.

<Benefits>

・Beautiful pattern.

・Reduces the monotony of the painted surface.

・Improved durability, rust prevention, and workability.