With increasing need of global environment conservation, moves toward strengthening the environmental regulations such as Air Pollution Control Law and Offensive Odor Control Act are seen in the world. It is also essential for each company to prevent local communities from having health damage and discomfort by odor. We provide solutions to the customers with such challenges with our wide variety of combustion type deodorizing devices. And we now newly offer a small sized RTO to shorten and simplify the construction work at site.

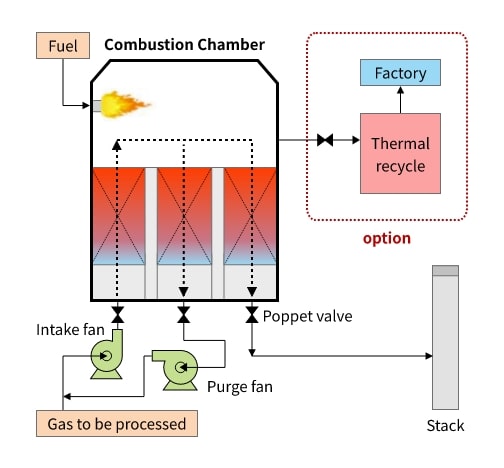

Regenerative Thermal Oxidizer(RTO)

This device contains a ceramic heat reservoir in its heat exchanger which enables the high temperature efficiency and low-fuel consumption.

Poppet Valve System

- Gas leak during conversion is substantially zero with the poppet type switching valve.

- Over 98% of high VOC performance

- Over 95% of temperature efficiency with the heat exchange method with heat reservoir.

- Fuel is not required if the gas to be processed is highly concentrated, and also it also enables exhaust heat recovery.

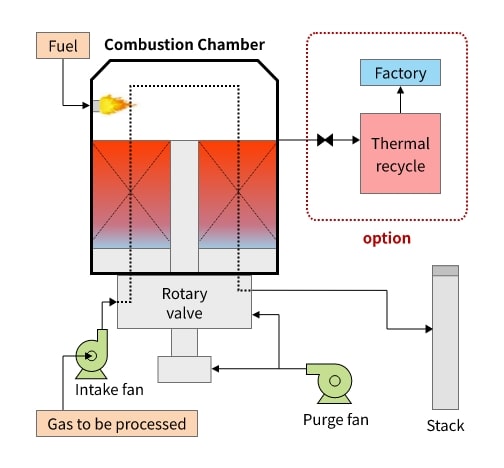

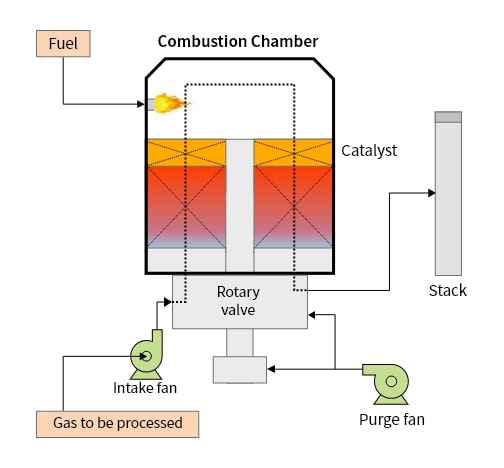

Rotary Valve System

- Has extremely low pressure fluctuation and no affect on production lines.

- Over 98% of high VOC performance

- Over 95% of temperature effectiveness with the heat exchange method with heat reservoir.

- Fuel is not required if the gas to be processed is highly concentrated, and also it also enables exhaust heat recovery.

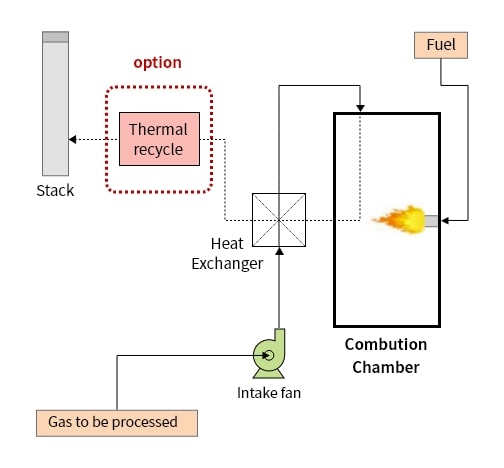

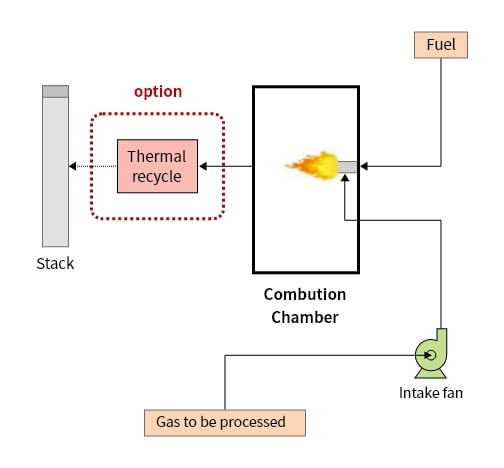

Thermal Oxidizer(TO)

This device can process various types of gas odor and produce stable hot air. Suitable for the operations for short gas odor generation time.

Heat Exchanger System

- Almost all types of VOC and odorous gases can be processed.

- Stable and high processing performance can be expected.

- Simple structure with the lowest initial cost.

- Enable to recover the high-temperature waste heat stably.

Direct Combustion System

- Enable to process high-concentration gas without dilution

- Stable and high processing performance can be expected

- Simple structure with the lowest initial cost

- Enable the waste heat recovery of about 750 ℃

Catalytic Oxidizer(CO)

This device can perform oxidative decomposition even at low temperature of 300-400℃ using deodorizing catalyst. This is the most suitable device for low temperature environment.

Plate Type Heat Exchanger System

- Performs oxidative decomposition of VOC and odorous gases above 300 degrees Celsius.

- Low-temperature operation with low fuel consumption

- Stable and high processing performance can be expected.

Regenerative Heat Exchanger System

- Performs oxidative decomposition of VOC and odorous gases above 300 ℃.

- Low-temperature operation with low fuel consumption

- Enable high fuel and more than 95 % of heat efficiency by heat exchange of heat reservoir.

- Stable and high processing performance can be expected.

VOCs Rotary Concentrator(RC)

This device converts VOCs gas with large gas flow with low concentration rate into the one with small gas flow and high concentration rate.

VOCs Rotary Concentrator(RC)

- Enable to downsize VOC combustion type deodorizer

- Enable to process low-concentrated gas to be processed with low fuel consumption

- Over 98% of high processing performance